Prototyping allows companies to troubleshoot and test specific components and product designs. This prevents large-scale manufacturing problems before they start. With prototyping, businesses can avoid wasting valuable time and resources.

When a large manufacturing project is looming, time is of the essence. Efficiency and speed are both essential to rapid prototyping.

At RJ Manufacturing, we provide rapid prototyping to organizations throughout many industries. This process involves the use of innovative machining technologies. We can fabricate testable scale models of components in the design phase.

Rapid Prototyping Technologies

To provide rapidly fabricated prototypes, we employ a range of modern machining technologies. Our engineers use CAD/CAM digital designs to manufacture any kind of prototype.

Our machining tools and fabrication methods can reliably realize digital design specifications. Because of this, we can provide fast prototype turnaround times to meet company deadlines.

Rapid prototyping is useful when businesses need to test possible designs. It is also useful when companies want to improve or enhance current products or components.

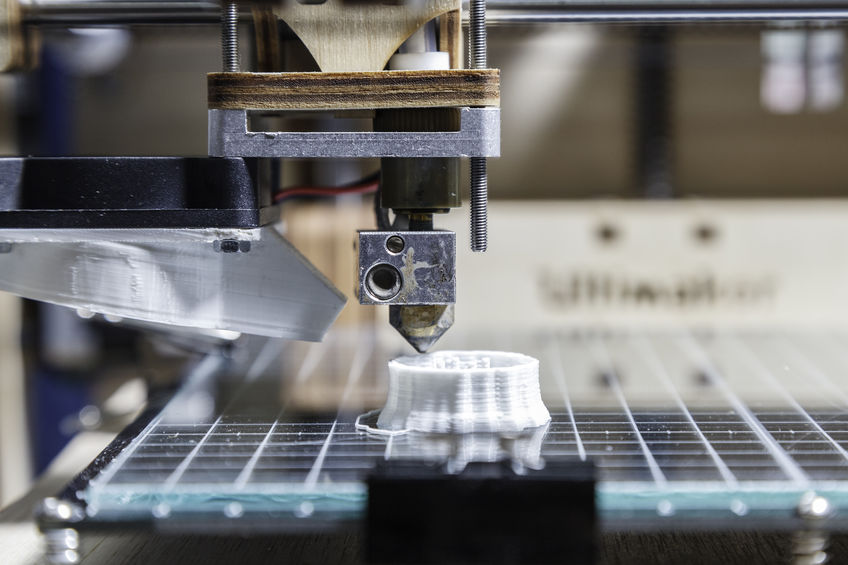

3D Printing

One common method of rapid prototype fabrication is 3D printing. This method is also known as “additive layer manufacturing.” In this type of manufacturing, material is gradually added, based on three-dimensional design specifications.

Through the use of 3D printing, RJ Manufacturing offers companies rapid prototype turnarounds. 3D printed prototypes feature a high level of fidelity to the initial design. Because our engineers implement digital designs, we can achieve incredible detail and specificity.

This allows companies to test product designs. They can adjust the product or component design as needed before beginning large-scale manufacturing.

Computer Numerical Control

Our engineers also use computer numerical control machines for prototype fabrication. Rather than adding materials to realize a design, CNC machines remove material from a larger piece. This process provides many benefits when making a prototype.

The CNC process utilizes three-dimensional, digital designs to create the prototype. At RJ Manufacturing, we have the capability for 3-axis, 4-axis, and 5-axis CNC machining.

We also have the capability for other forms of prototype manufacturing. Rapid prototyping is an excellent way to develop product designs in a cost-effective manner. No matter what the project specifications may be, the engineers at RJ Manufacturing can create your design with ease.