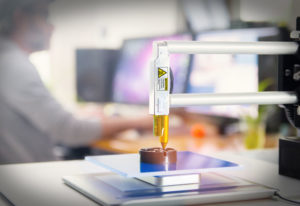

When you are looking for a manufacturing firm for your new product or prototype, one of the terms you’re going to hear thrown around is “CNC machining.” Machining is simply the process of removing material from a block to create a part, product, or prototype. Computer numerical control (CNC) machining refers to the use of computer-assisted technologies in both design and manufacturing.

CNC machining is the gold standard for new manufacturing projects. Unless your product will be created solely from sheet metal, your project probably requires at least some machining. Computer assisted design (CAD) software combined with powerful customized CNC software allow for the most precise geometries and measurements possible.

CNC machining is perfect for the start up.

Are you the idea guy rather than the technical guy? If so, your only concern is making sure that your design comes to fruition. That means you require the best in precision and quality. Our engineers can use CAD software to design a prototype or other project and use that design to program the CNC machine. The CNC machine then controls tools to mill, grind, cut, drill, or bore into the metal to create your piece with the ultimate precision.

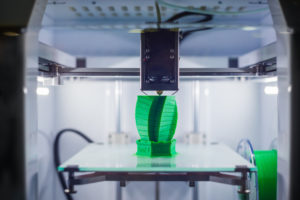

CNC machining is best for your bottom line.

The entrepreneur in you is always going to want to go with the option that is best for your bottom line. At the end of the day, what is going to make you the most money? CNC machining is a wise investment for new parts or products because it can easily be scaled to the quantity desired. After the prototype is finished, tested, and accepted, production for distribution can begin immediately with little additional investment.

Still not sure CNC machining is right for your project? Contact us today for more information or assistance.