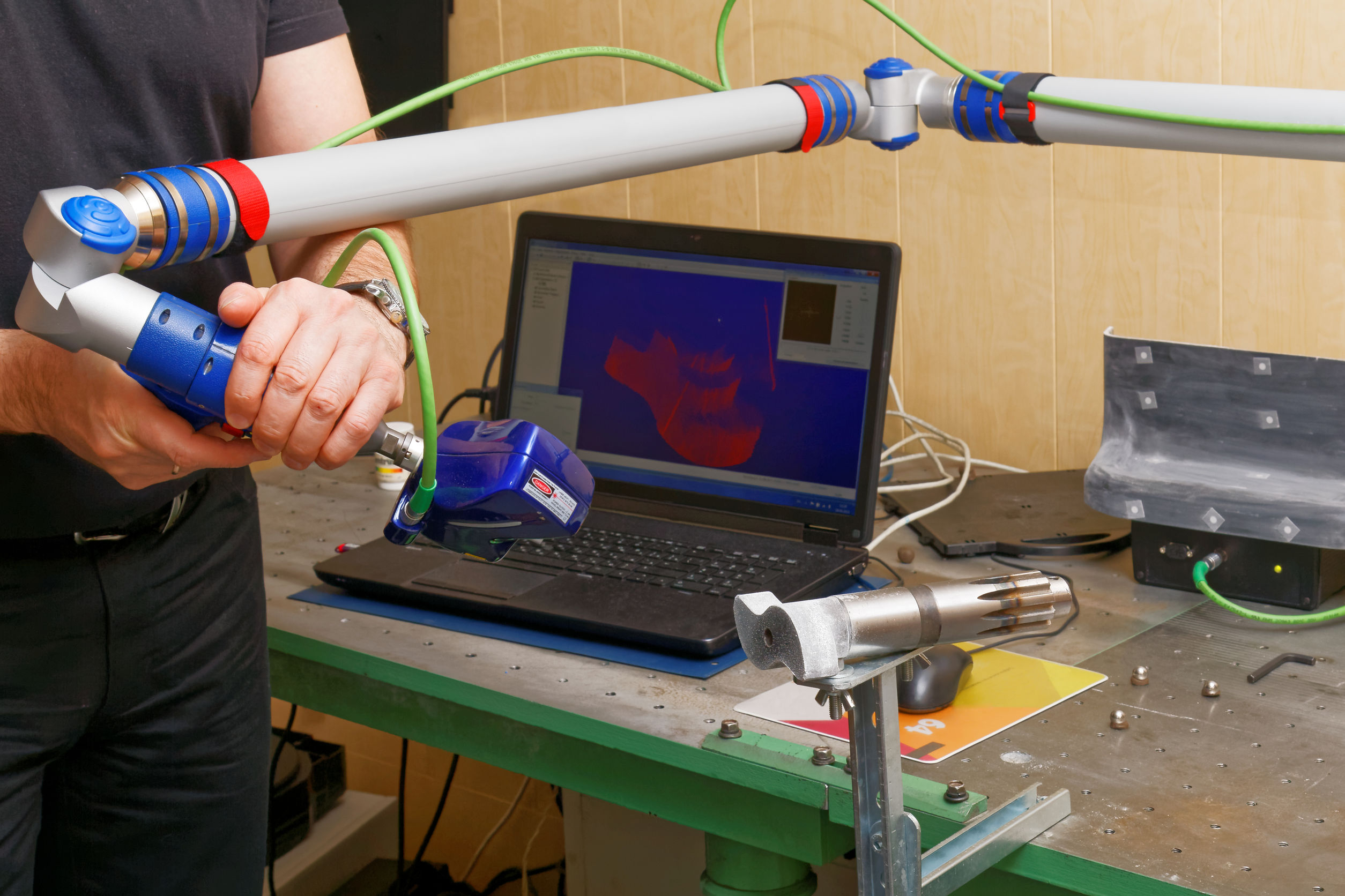

Reverse engineering is the process of dismantling a product to understand how it works, often to reassemble the product or build an improved version of it. While patents or copyrights may protect certain components, companies may be able to reverse engineer these products to create similar or competitive versions to use or sell.

This post will explore three applications of reverse engineering and illustrate its usefulness in the manufacturing industry.

To Use as a Learning Tool

Sometimes, reverse engineering can simply be a learning tool. Up-and-coming engineering technicians may benefit from examining a product to understand how its mechanical and electrical components come together. This knowledge may be valuable not only for repair but also for designing future products.

To Manufacture an Improved Product

Reverse engineering can also be used to discover flaws or weak points in a competitor’s product, which can give you a roadmap to creating an improved or more cost-effective version.

This can be a great way to attract or retain customers who may appreciate the superior quality or lower cost of the product you’ve provided, thanks to the knowledge gained through reverse engineering.

To Create Compatible Products

Many times, manufacturers offer products that contain proprietary features. This means that you can only use accessories that the manufacturer produces because of a unique design shape or the way that the mechanical parts are meant to fit together.

With reverse engineering, companies can unlock the secret of these features and create products that are compatible with the tool or device, thus providing a competitive option for future customers.

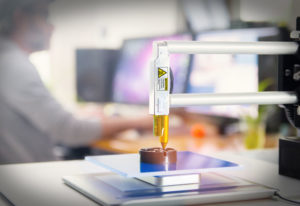

Contact RJ Manufacturing

RJ Manufacturing is committed to best practices in engineering. We offer rapid prototyping, 3D printing, welding, and a variety of other specialized services. When you need professional expertise, contact the friendly, resourceful team at RJ Manufacturing.