Prototyping your product is the best way to test and modify it before you transition into the final manufacturing phases. By making a prototype at various developmental stages, you can confirm that your creation is functioning in the ways that it is supposed to. This process will also give you a working model so that you can make changes with the product in hand.

Despite the benefits of creating a prototype, it can be expensive to repeatedly machine new versions. Fortunately, PLA and ABS are very affordable materials that can help you stay within your budget while also giving you a high-quality prototype.

What Is PLA?

PLA (polylactic acid) is a polymer that is derived from renewable food products like sugarcane and corn starch. PLA is referred to as a bioplastic because it is made from biological materials, as opposed to petroleum reserves.

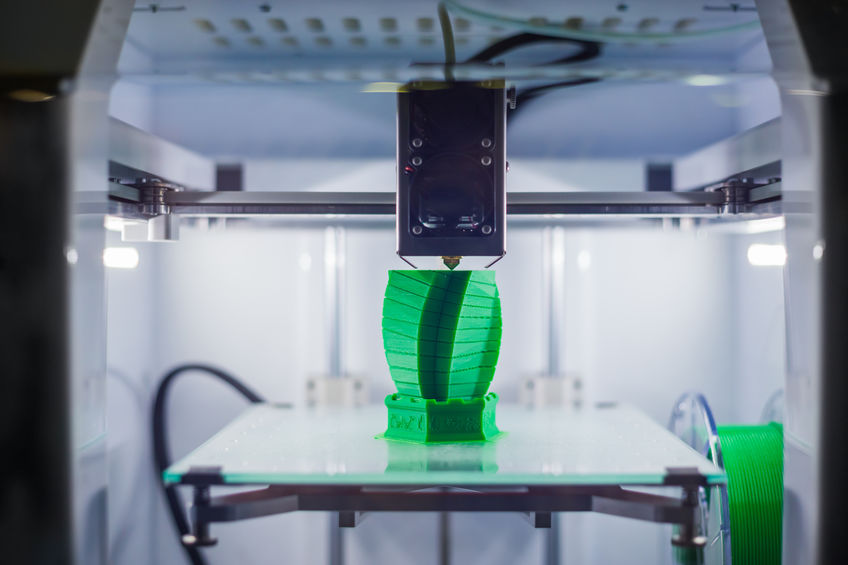

It is used for prototyping because of its low cost and pliability. PLA is most commonly available as a 3D printer filament or as plastic pellets. PLA comes in a wide array of color options. It is even biodegradable, which helps cut down on waste as you create prototypes.

What Is ABS?

Acrylonitrile butadiene styrene (ABS) is a versatile thermoplastic that is great for producing prototypes. It can be heated and cooled more than once without serious degradation. This trait makes ABS easy to recycle and incorporate into other products. However, its low melting point makes it a poor choice for high heat applications.

Which Material Is Better for My Project?

Both ABS and PLA are suitable for a variety of project needs. They are cost-effective and easy to work with, allowing you to rapidly create your prototype or scale model.

If you need rapid precision fabrication services, RJ Manufacturing can help. Consult with our experienced prototyping and engineering team to see what we can do for you!