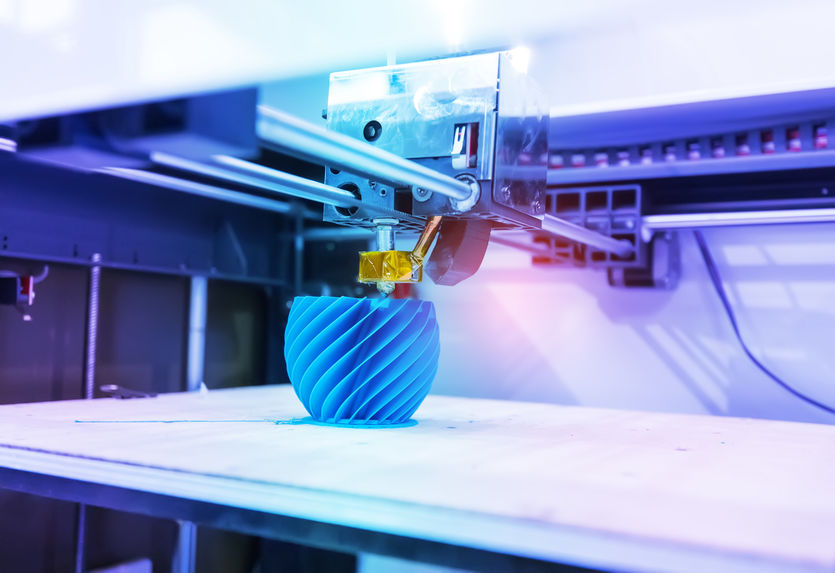

There is no doubt that 3D printing is a common technology used in engineering and manufacturing today. While 3D printing is most often used to create working prototypes or 3D models that investors can hold in their hands, it can also be used to create lasting moving parts for your product, when warranted. Here is what you need to know about the different types of 3D printing and when they should be used.

SLA 3D Printing for Manufacturing

The SLA, or Stereolithography, 3D printing method is the original process developed in the 80s. SLA uses a laser to cure liquid resin in hardened layers to build a 3D model or even product with moving parts. The SLA 3D printer offers durability, functionality, and flexibility to work within your desired parameters.

In manufacturing, SLA 3D printing is usually used to create working prototypes before true manufacturing begins. This is because it is cheaper to 3D print the project and have a mistake than to build the product from expensive materials without a flawless product.

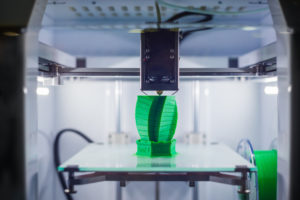

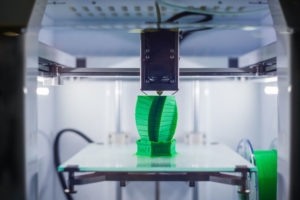

PLA 3D Printing

PLA 3D printing is the most popular because it is the least expensive and most widely available. Polylactic acid has some advantages over SLA, but not in performance. If you’re just making your very first prototype or physical model of your project, PLA will work for that purpose. It’s a good idea, in fact, to use PLA at this stage to keep costs low while the project is being refined by our engineers and your team. After all of the bugs have been worked out, the project should move to an SLA 3D printer for the next stages of the project.

Are you confused about the different types of 3D printing, when they are used, or how they might apply to your project? Leave all of the work up to the professionals and sit back while we bring your idea to fruition. Contact us today to get started.